In the first half of the year, Tramontina Cutelaria (RS) completed two construction works in the Starflon Division. The Reception 2 - Starflon Division, with 370 m² of built-up area, destined for trucks, improving flow and access controls, and the expansion of 7,860 m² of built-up area in the Disc Preparation sector, doubling its area. The pavilion already has part of the area with a height of 18 meters for future placement of an automated storage system. The entire pavilion follows the concepts of ventilation and natural lighting, saving energy.

At Tramontina Garibaldi (RS), one of the new features is the 3 new pieces of equipment for brazing concrete drills, which have the purpose of automatically welding the insert with the stem, which are used in the manufacture of drill bits for concrete. It is a considerable increase in this production process, going from 140,000 pieces/month to 350,000 pieces/month in the production of concrete drills. With the new equipment, in addition to the increase in production, it will be possible to have a better product standardization.

Another investment at the Garibaldi (RS) unit was in yet another modern, latest technology from Japan, to optimize the construction of molds and devices in the mechanics sector, which now has 5 Mazak machining centers.

The Mazak FJV 35/60 model is intended to increase the machining capacity for molds, parts for devices, and machines for production. With this acquisition, the machining capacity increased by 20% in two work shifts.

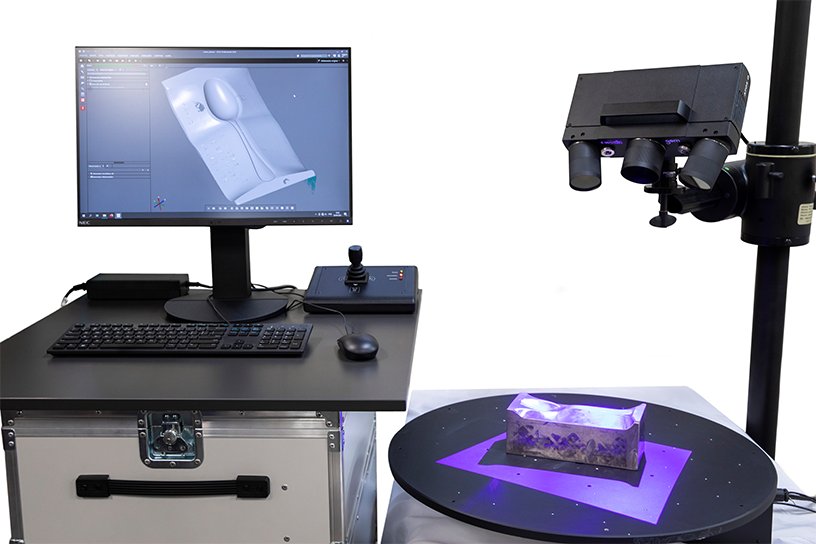

At the Farroupilha (RS) unit, to improve and streamline the flatware manufacturing process, there was the acquisition of a high-precision 3D optical scanner manufactured by the German company GOM. With this scanner, it is possible to capture in greater detail the complex surfaces that make up the flatware carving.

Also, in Farroupilha (RS), the implementation of the MES system developed by Tramontina’s in-house team was started on its production lines. The MES System - Manufacturing Execution System, or Manufacturing Execution System - aims to monitor equipment operation, extracting and recording important information for the efficient management of processes. 67 strategically important manufacturing lines and cells were selected to receive the system. The deployment started at the Sauce Pans factory and will continue through the other factories in accordance with the priorities established in the Project. With the use of this system, any deviations in the equipment’s functioning can be detected much more quickly, allowing the necessary corrections to be applied to prevent drops in productivity.

The unit also acquired an automatic vertical warehouse to store components in the warehouse designed to meet all the assembly lines of kitchen equipment and the supply of external technical assistance to meet the needs of components for pans, small appliances, kitchens, and other areas. Smaller volume items are kept there, totaling around 2,000 references.